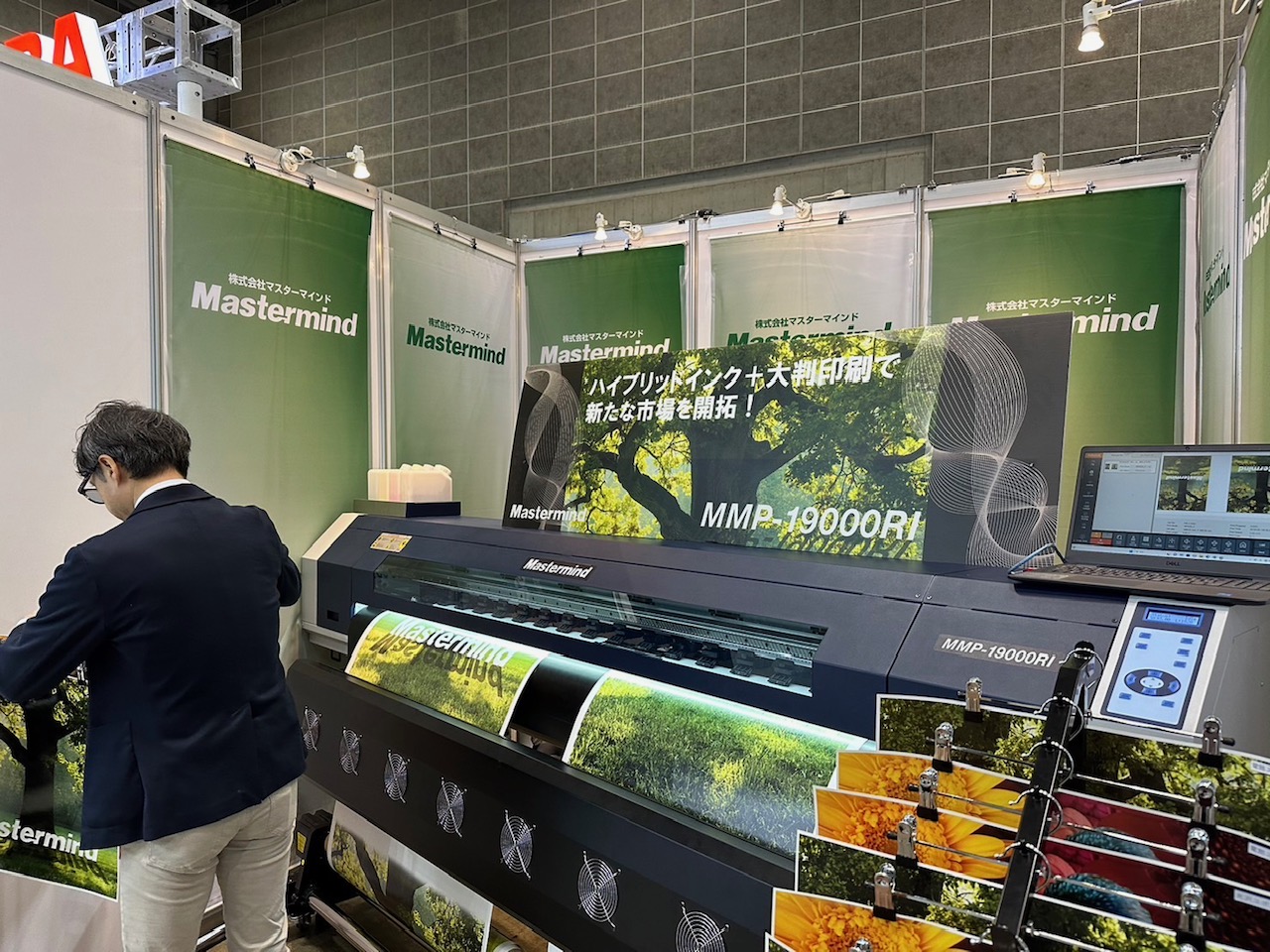

Introducing the MMP-19000Ri, a roll-to-roll printer equipped with hybrid resin ink that supports low temperature and low VOV, capable of printing on non-inkjet media!

Usage examples of the MMP-19000RI

1. By printing on 'raw Yupo paper' without an inkjet receptive layer, media costs are reduced. Additionally, printing on media that is easily affected by heat, such as Yupo paper, is made possible.

2. Printing directly on non-inkjet media, such as offset coated paper and kraft paper, to make the best use of surplus paper!

3. For printed materials that require a glossy or uneven finish, which is difficult to achieve with UV inks!

4. Water-resistant, so can be used indoors without lamination, e.g. on banners!

5. Rapid volatilization of VOCs allows laminating to be carried out immediately, reducing production time.

2. Fast Drying.

▶ The heat requirement is relatively low at 40-50°C.

▶ Can be used for a wide range of materials, as it can print on heat-sensitive materials.

▶The volatile components that occur after printing are constantly removed, preventing blotting of the printed surface.

▶ Volatile organic compounds (VOCs) are produced, but they are less than those of regular Ecosol and the volatilization time is very short.

▶ Can be laminated immediately after printing (or used as is without special treatment for indoor applications).

3.Glossiness

▶ Fixing resins and dispersions, which are the basic elements of the ink, were developed from scratch.

▶Fixing resins are completely soluble in safe solvents and are safe to use.

▶ Can be made into low-viscosity, high-fixation inks.

▶Pigments are chosen to be weather resistant.